Infrastructure

Our manufacturing units follow various processes and methodologies to achieve

Manufacturing Excellence. Some major USP’s of our manufacturing units include

● Stringent raw materials procurement policies

● Process adherence is each and every stage of the manufacturing process.

● Compliance with Government norms and regulations.

Six Sigma Approach – We follow a data driven approach eliminating defects to achieven Operational Excellence. This approach is used vastly with vendor management (procurement of raw materials) eliminating the secondary need for quality inspections.

Lean Manufacturing – We strive towards eliminating waste in the system without sacrificing productivity thus improving Quality, Time and Cost.

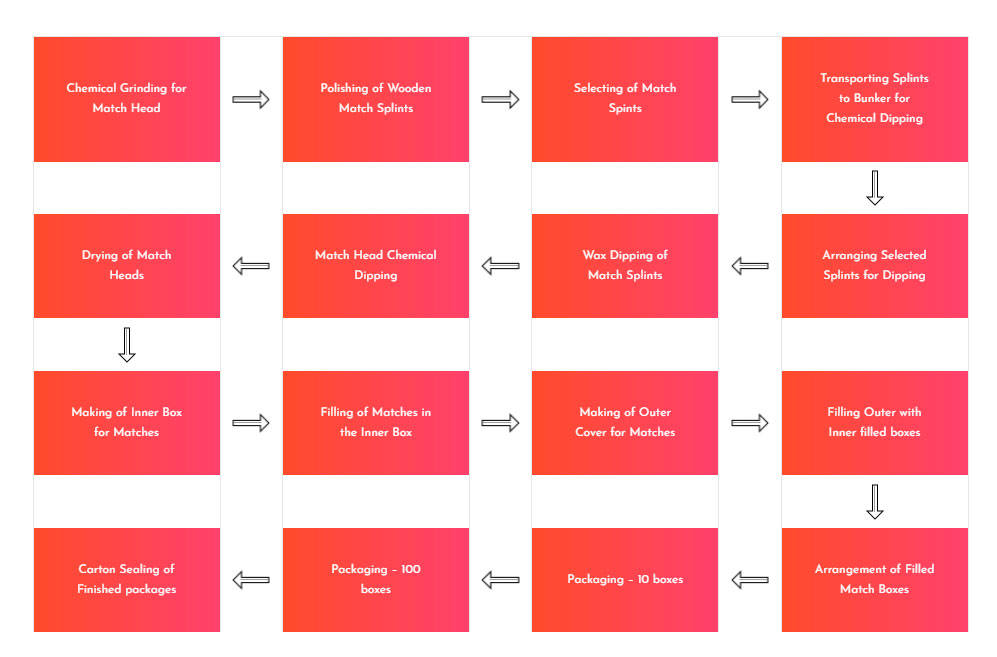

MANUFACTURING PROCESS

| Chemical Grinding for Match Head | Polishing of Wooden Match Splints | Selecting of Match Spints | Transporting Splints to Bunker for Chemical Dipping | |||

| Drying of Match Heads | Match Head Chemical Dipping | Wax Dipping of Match Splints | Arranging Selected Splints for Dipping | |||

| Making of Inner Box for Matches | Filling of Matches in the Inner Box | Making of Outer Cover for Matches | Filling Outer with Inner filled boxes | |||

| Carton Sealing of Finished packages | Packaging – 100 boxes | Packaging – 10 boxes | Arrangement of Filled Match Boxes |

| Chemical Grinding for Match Head |

| Polishing of Wooden Match Splints |

| Selecting of Match Splints |

| Transportaing Splints to Bunker for Chemical Dipping |

| Arranging Selected Splints for Dipping |

| Wax Dipping of Match Splints |

| Match Head Chemical Dipping |

| Drying of Match Heads |

| Making of Inner Box for Matches |

| Filling of Matches in the Inner Box |

| Making of Outer Cover for Matches |

| Filling Outer with Inner filled boxes |

| Arrangement of Filled Match Boxes |

| Packaging – 10 boxes |

| Packaging – 100 boxes |

| Carton Sealing of Finished packages |

MANUFACTURING PROCESS